Ultimate Overview to Installing Long Lasting Epoxy Floors in Residential Spaces

When it comes to changing property rooms with durable epoxy floorings, a systematic approach is essential. There's one aspect typically ignored that can considerably influence the durability and top quality of the epoxy flooring.

Selecting the Right Epoxy Flooring System

Picking the ideal epoxy floor covering system is an essential step in making sure longevity and performance in property rooms. Epoxy flooring offers durability, very easy maintenance, and aesthetic charm, making it a prominent option for property applications. When selecting an epoxy system, aspects such as the sort of epoxy, degree of longevity called for, design preferences, and spending plan constraints need to be thought about.

There are different kinds of epoxy floor covering systems readily available, including water-based epoxy, solvent-based epoxy, and 100% strong epoxy. Water-based epoxy is easy and environment-friendly to apply, making it ideal for household usage. Solvent-based epoxy gives a much more durable finish but discharges solid smells during installment. 100% strong epoxy is the most resilient choice, suitable for high-traffic areas in residential spaces.

Preparing Your Residential Space

When considering the installment of long lasting epoxy floors in household spaces, appropriate preparation of the area is fundamental to making certain a durable and effective application. The very first step in preparing your household space for epoxy floor covering is to extensively cleanse the surface area.

These need to be filled and leveled to develop a smooth and also surface for the epoxy covering to be used. Furthermore, check for dampness concerns as too much dampness can trigger the epoxy to bubble or peel. Welding Inspection Service.

Lastly, guarantee proper ventilation in the room during the installation procedure to permit the epoxy fumes to dissipate. Adequate prep work of the house establishes the foundation for a successful epoxy flooring application.

Applying Epoxy Finishing

To start the process of applying epoxy finishing, thoroughly mix the epoxy resin and hardener according to the manufacturer's guidelines. It is vital to adhere to the advised blending ratios exactly to make sure the epoxy treatments appropriately and accomplishes optimum longevity. When the epoxy elements are mixed, put the blend onto the prepared flooring surface area in a bow pattern.

Making use of a roller with a medium-nap cover, spread out the epoxy equally over the flooring, working in manageable sections to stop the epoxy from drying as well quickly. Make certain to back-roll the applied epoxy to eliminate any have a peek at this site kind of puddles or uneven locations, guaranteeing a constant and smooth coating.

Enable the epoxy finish to cure according to the manufacturer's directions before proceeding with any type of more see this site steps to make sure a resilient and lasting coating.

Making Sure Correct Curing and Drying Out

Reliable treating and drying processes are necessary to achieve the desired sturdiness and durability of epoxy floorings in residential areas. Proper curing involves offering the epoxy covering enough time to harden and bond totally to the substratum. This procedure commonly takes about 24 to 72 hours, relying on the certain item used and environmental problems. Throughout this duration, it is vital to restrict foot web traffic and avoid placing heavy objects on the flooring to prevent any damages or blemishes.

Appropriate airflow aids the epoxy covering to cure evenly and avoids any kind of concerns like gurgling or irregular drying out. It is advised to follow the maker's guidelines for healing and drying out times to ensure ideal results and optimize the sturdiness of the epoxy floor in property settings.

Prolonging and maintaining Epoxy Floor Lifespan

Proper maintenance methods play an important function in expanding the life-span of epoxy floorings in domestic settings. Routine cleansing is essential to stop dust and particles from scraping the surface of the epoxy floor.

To further protect the epoxy flooring, take into consideration using a new overcoat every couple of years, specifically in high-traffic areas. By complying with these maintenance ideas, property owners can ensure their epoxy floorings continue to be sturdy and aesthetically appealing for years to come (Welding Inspection Service).

Verdict

Finally, setting up resilient epoxy floorings in property spaces requires mindful factor to consider of the epoxy floor covering system, comprehensive prep work of the area, proper application of the epoxy covering, and making sure right healing and drying procedures. By complying with these steps faithfully, home owners can accomplish a visually enticing and durable epoxy flooring that boosts the resilience and aesthetic appeals their website of their living areas.

When it comes to changing household spaces with durable epoxy floors, a systematic strategy is vital. When selecting an epoxy system, aspects such as the type of epoxy, degree of sturdiness called for, design choices, and budget plan restrictions must be thought about.

There are various kinds of epoxy flooring systems readily available, consisting of water-based epoxy, solvent-based epoxy, and 100% solid epoxy.When thinking about the installment of long lasting epoxy floors in household spaces, adequate prep work of the area is fundamental to guaranteeing a lasting and successful application.To start the process of applying epoxy finishing, thoroughly blend the epoxy material and hardener according to the manufacturer's directions.

Jaleel White Then & Now!

Jaleel White Then & Now! Brandy Then & Now!

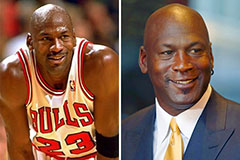

Brandy Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!